A TYPICAL CONSTRUCTION CYCLE WITH THE OVERHEAD MSS

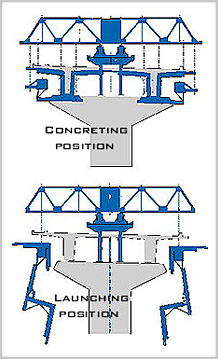

1. After concreting, curing and tensioning of cables, the Main Girder (or girders) is (are) lowered by the Main Jacks down to the Launching Wagon (located at the supports).

2. The bottom formwork (box section) or interior formwork (double T) is lowered by means of winches or hydraulic cylinders. The ext. part of the outer formwork will be lowered, too.

3. The MSS will be launched to its new position (next span). The rear support is connected to the Main girder(s) and will “automatically” be launched to its new position together with the MSS.

4. The formwork panels will be closed again (by means of either winches or hydr. cylinders).

5. The MSS will be lifted by the Main Jacks.

6. The formwork will be adjusted (if required) by adjusting the hanger bars.

7. When placing of reinforcement and tendons is finished, the MSS is ready for concreting of the next span of the superstructure.

8. For box girder bridges: After placing the reinforcement and tendons of the bottom slab and webs, the Internal Formwork is moved to its next position.

9. During concreting/curing, the now “rear” main support will be dismantled and re-installed at the next (3rd) pier.