TYPICAL ERECTION METHODS, CONDITIONS AND FEASIBILITIES

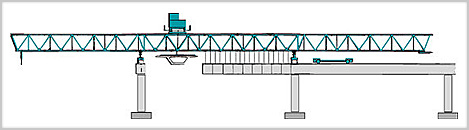

Our gantries (LG) can be used for both balanced cantilever as well as for infill span-by-span erection. Depending on the project dry joint or wet joint erection is required.

1. Featuring segmental bridges with dry or glued joints, using erection methods like infill-spans and balanced cantilever.

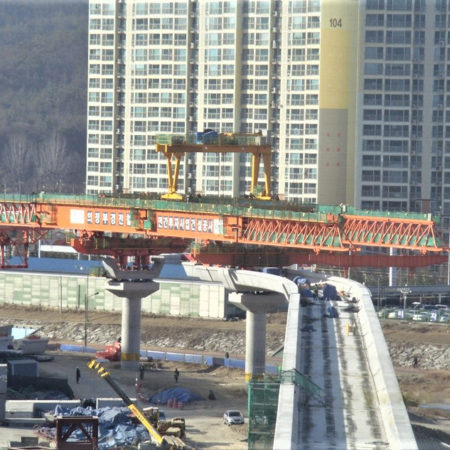

2. Special hinged overhead gantries (with up to 6 hinges) have been supplied to accommodate tight horizontal curvature, down to 100m radii.

3. Side-launching of gantry to accommodate erection of separate parallel double and triple tracks, as well as bifurcation spans.

4. Vertical climbing of gantries to allow access for side shifting to neighbouring bridges, and to accommodate tight vertical curvature and steep longfall.

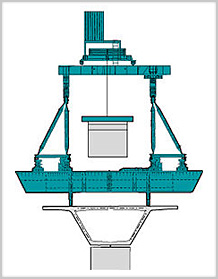

5. Fully and partly final post-tensioning carried out while the whole span is still suspended to the gantry, without need to use special plunger arrangement at each end.

6. “Glue-as-you-go”, erecting segments without any or only limited double handling.

7. Balanced cantilever and infill-span erection with same gantry.

8. Cranes capable of walking through hinged transitions (also noses).

9. Gantry can lift and adjust whole span in level and line (vertical and transverse adjustment).

10. Gantry is selflaunching, transports also supports by its own crane.

11. Aux. equipment for erecting pre-cast wings at 2nd stage ( if needed).