An advance, fast and reliable solution for extreme tight radius erection of modern pre cast segmental bridges.

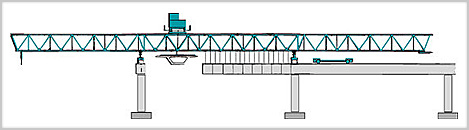

NRS Launching Gantry (LG) System – The recognized technology for construction of modern bridges with tight horizontal radius and has become one of the most widely used for the construction of precast segmental bridges.

NRS had grown rapidly its reputation as one of the most recognized suppliers of Launching Gantries for “Span by span” and Balance cantilever methods of construction.

Several features that makes our system more widely acceptable by contractors with remarkable success in many challenging bridge projects worldwide includes:

- The use of “Hinge” solution to overcome bridges with tight horizontal curves, including a specially designed gantry crane for the kinked hinges.

- “Glue-as-you-go” concept for wet joints segmental bridges to reduce double handling of segments.

- “Turnaround” concept to reduce stacking of segments within a span.

- Unique Gantry crane structure to enable smooth movement around hinges

- Fail-proof hydraulic launching system.

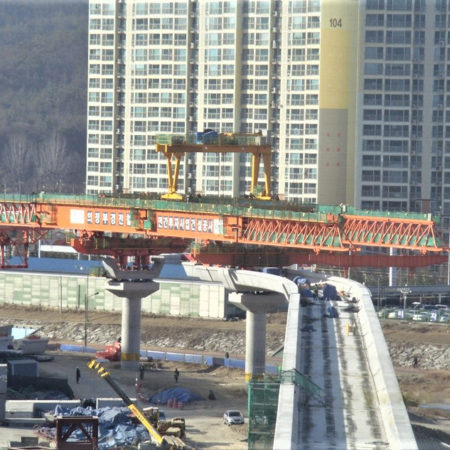

HINGE LAUNCHING GANTRY (LG) – An Innovative Solution for Curve Bridges

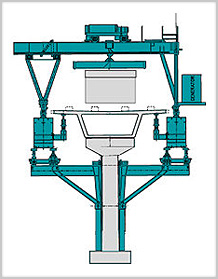

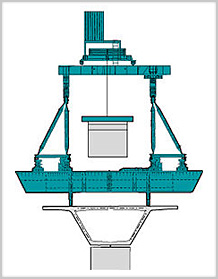

To overcome the difficulties of erecting spans on curve with the conventional straight LG, NRS developed in the early 90’s the innovative “hinged” concept, which allows the articulation of the LG to handle segment erection and launching operation. The hinge concept enables span erection on horizontal radius as small as 75m (40m span) previously never thought it is possible without the need of additional external temporary supports.

As many as 6 hinges, each regulated by hydraulic cylinders, have been used in a single LG. A specially designed gantry crane is also used to travel smoothly through the kinked hinges along the LG during lifting and placing of segments.

The hinge concept remains today a unique feature well known in the industry for erection of precast segmental bridges on tight curves. This solution has been proven successful in many major projects particularly in Metro or Light Rail Transit projects where tight curves are quite common along the alignment. The hinged LG offers significant advantages over the conventional straight gantries in terms of erection speed and cost of construction.

SPECIFIC DETAILS